key facts

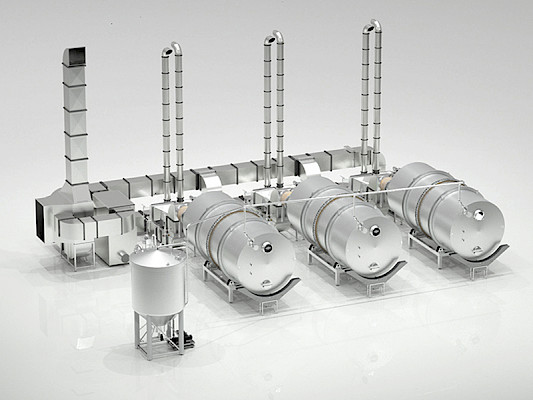

- fully automated process: guarantees high consistency of the products

- homogenious products

- flexible - all cerials and malts, kilning temperatures up to 265°F

- hygenic and clean - products are all contained, all stainless steel

- small footprint - safe on additional vessels and equipment