our products for the beverage industry

recipe development

Product development for one beverage product

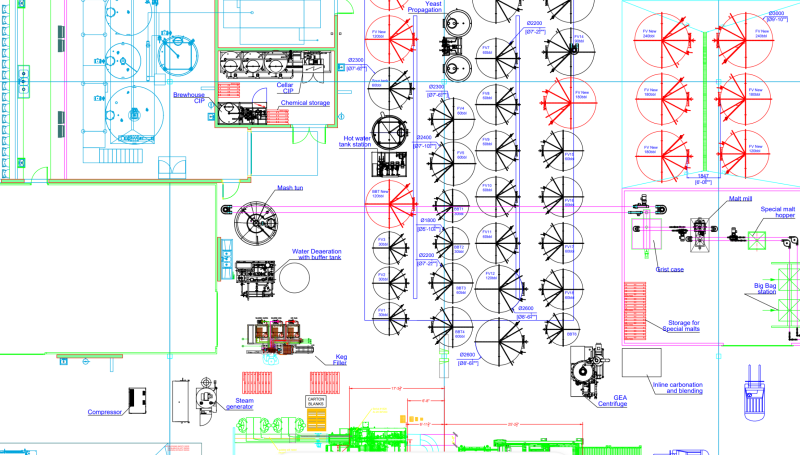

layout planning

Technical / sanitary and electrical plan of a brewery or beverage production in 2D

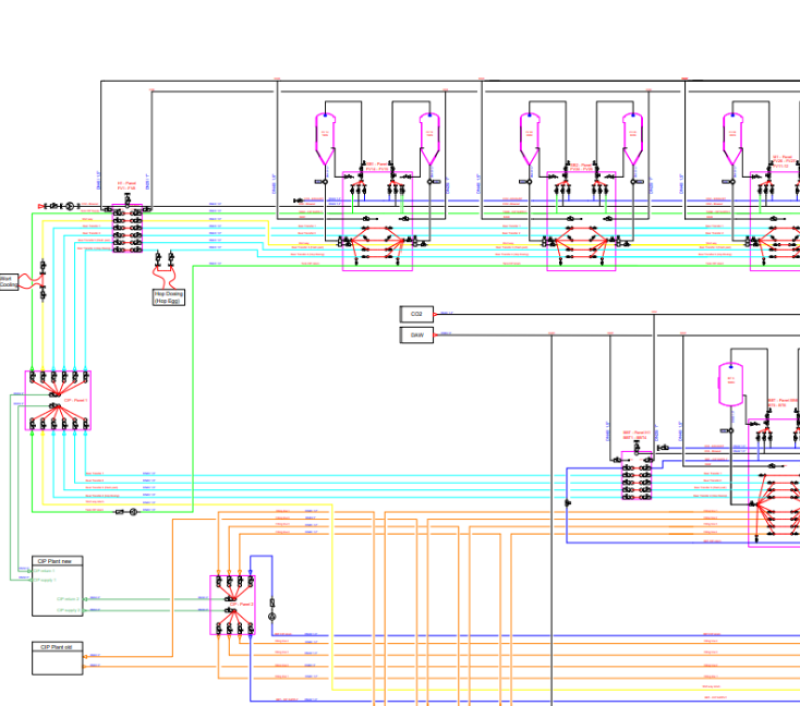

detail engineering

Detailed 3D and 2D engineering for beverage companies

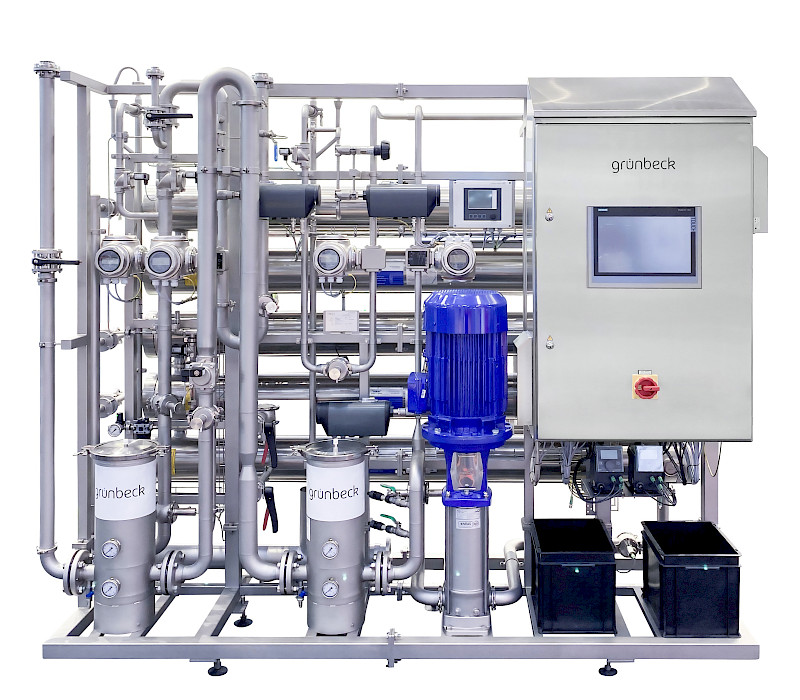

utility selection

Steam boiler, glycol unit and air compressor engineering and selection

project management

Project management, time planning and interface coordination

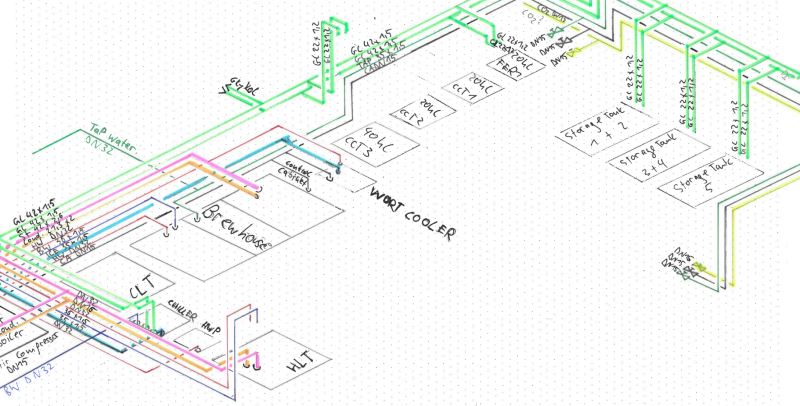

piping solutions

we specialize in planning, delivering and implementing complete piping solutions for the beverage industry

installation planning and support

Process piping and installation plan

installations on-site

we install your system with local workforce and specialists in their field rigging, mechanical, welding and electrical works

spare parts

we supply your brewery with all needed spare parts

Kaspar Schulz Drum Malting System

2 - 25 t/batch

Fully automated and high efficient solution for state of the art malt producers, farmers, distilleries and breweries.

Grain and Malt Handling Systems

up to 100 t/h

for Malt Houses, Breweries, Distilleries, and Bakeries

two roller grist mills

capacity from 250 - 500 kg/h

the workhorse for pub and craft breweries

four roller grist mills

capacity from 800 - 3,000 kg/h

improve your efficiency and lautering times

six roller grist mills

capacity from 1,000 - 14,000 kg/h

get the highest efficiencies and perfect grist composition - endosperm mashing possible

brewing block from Kaspar Schulz

capacity from 2,5 - 40 hl/batch

the Kaspar Schulz "brewing block" is a complete and preinstalled brewhouse system for breweries in stainless steel, combining all components of brewing in a single system, from pre-mashing to whirlpool

copper brewhouse from Kaspar Schulz

capacity from 2,5 - 100 hl/batch

a traditional brewing system custom-built by the Kaspar Schulz copper smith

industrial brewhouses from Kaspar Schulz

capacity from 2,5 - 300 hl/batch

production brewing systems with state of the art technologies for beer with character

distilling system from Kaspar Schulz

Brewers´Still - specially designed for breweries

capacity pot sizes of 250 to 1000 litres

vacuum expansion evaporator from Kaspar Schulz

Kaspar Schulz vacuum expansion evaporator

aeration system

capacity from 5 - 1,500 hl/h

good fermentation requires yeast in top condition and the correct aeration of wort and yeast before pitching

yeast propagation system

vigorous and strongly fermenting yeast in a physiologically flawless state as an essential requirement for high and consistent beer quality and increasing biological safety

open fermenters

5 - 800 hl capacity with automated cleaning

for bottom and top fermented beers

open fermenters are a traditional method of fermentation which allow natural air exchange - build a personal relationship to your beer by having a daily look at the beer

tanks from Kaspar Schulz

finest quality stainless steel vessels combine complex technical solutions and cutting-edge workmanship with quality and top-of-the-range aesthetics

horizontal lagering tanks from Kaspar Schulz

finest quality stainless steel horizontal lagering tanks combine complex technical solutions and cutting-edge workmanship with quality and top-of-the-range aesthetics

CIP System

manual, semi automatic and fully automatic solutions

for cleaning of fermentation and storage tanks, process lines, filling lines and other units.

Branches: breweries, beverage companies, dairy and food manufacturing

flash pasteurizer

our flash pasteurization systems contain the gentlest state-of-the-art process for the biological preservation of beers

filter system

filtration has a decisive influence on the quality of the finished beer, as it ensures microbial, colloidal and flavor stability

Kaspar Schulz Wizard: production of non-alcoholic beer

from 20 - 80 hl per production day - integrated flash pasteurization and blending unit

hopdosing system from Kaspar Schulz

Kaspar Schulz hop rocket - flexible use for hop pellets and cone hops in different process steps and areas